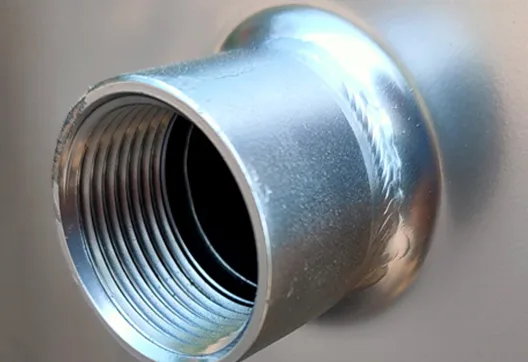

The 304 stainless steel water tank is assembled and welded from stainless steel water tank stamping plates. The stainless steel water tank plates are assembled and welded by argon arc welding. If the weld seam is not properly treated, it is very easy to cause rust around the weld seam, which further affects the main body of the stainless steel water tank, causing corrosion of the water tank and water pollution.

Stainless steel will undergo heat treatment on the surface during processing and welding, resulting in black oxide scale. During the welding process of the water tank, oxidation can be observed in the discolored area, and the corrosion rate is related to the thickness of the oxide layer. Compared with the oxide layer before stainless steel welding, the oxide layer in the discolored area is thicker and the composition changes (nickel chromium reduction), thereby reducing the local corrosion resistance. In general, when welding stainless steel water tanks for domestic water tanks, fire water tanks, softened water tanks, and other purposes according to the instructions, there is no need to treat the welds.

During the welding process, excessive welding occurred on the stainless steel water tank plate, resulting in damage to the surface passivation film. Chemical treatment of the stainless steel surface can be carried out using pollution-free acid pickling passivation. Acid pickling can make the entire surface of the stainless steel more balanced. After acid pickling passivation, iron and iron oxides can be dissolved, making the stainless steel surface rich in chromium.

304 stainless steel has the advantages of high strength, high wear resistance, corrosion resistance, and not easy to rust. Stainless steel water tank plates stamped with first-class stainless steel raw materials can be welded into stainless steel water tanks, which are widely used in people’s lives.