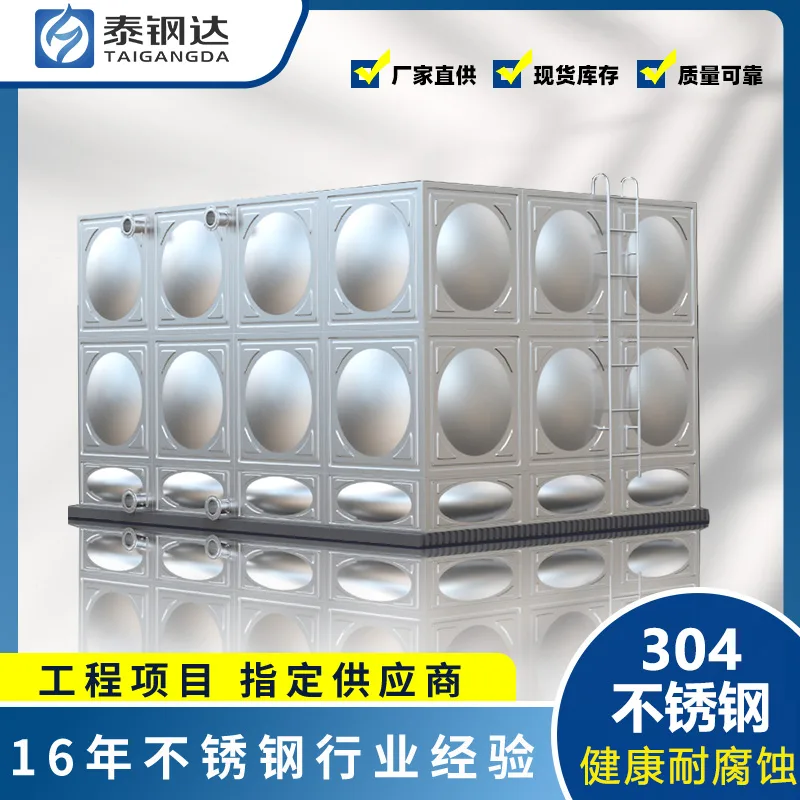

1. Inconsistent appearance of stainless steel water tank: Only pickling and passivating the weld seam also results in uneven appearance, affecting the aesthetics.

2. Uneven polishing and passivation: After manual polishing and pickling, it is difficult to achieve a uniform and consistent treatment effect on larger workpieces, resulting in an unsatisfactory uniform appearance and high labor and auxiliary material costs.

3. Scratches are difficult to remove: All acid pickling and passivation cannot remove various scratches that occur during the processing, and cannot remove impurities such as carbon steel and splashes that adhere to the surface of stainless steel due to scratches, welding splashes, etc., which can cause chemical corrosion or electrochemical corrosion and rust in the presence of corrosive media.

4. Weld seam defects: Weld seam defects are severe and are repaired by manual mechanical polishing. The polishing marks that occur result in uneven appearance and affect aesthetics.

5. Pickling ability is limited: Pickling passivation paste is not omnipotent, and it is difficult to remove the black oxide skin produced by plasma cutting, flame cutting, and other processes.

6. Scratches caused by human factors are relatively severe: During the lifting, transportation, and structural processing, scratches caused by human factors such as bumps, delays, and hammering are relatively severe, making surface treatment more difficult and also the main cause of rust after treatment.

7. Equipment elements: Scratches and creases formed during the bending and folding process of profiles and plates are also the main causes of rust after treatment.

8. Other factors: During the procurement and storage process of stainless steel raw materials, collisions and scratches that occur during lifting and transportation are also quite severe, which is one of the reasons for corrosion